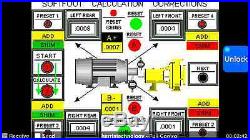

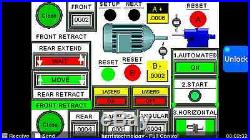

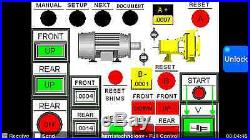

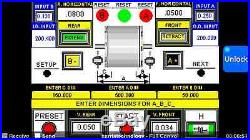

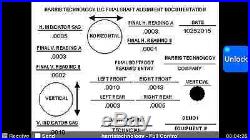

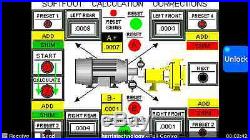

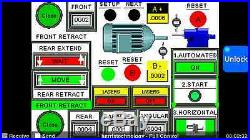

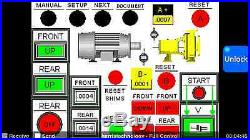

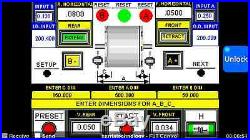

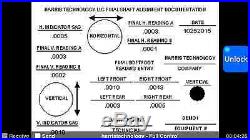

ROBOTALIGN_2016 AUTOMATED INDUSTRIAL MOTOR SHAFT ALIGNMENT DEMO SYSTEM. Control & Computing Module with Robotic manual & automated positioning systems software. 2 Fowler/Sylvac Mark V Digital Indicators. 6 graphic icon represented Color Touchscreen. Ethernet Router that enables Iphone or Android PDA remote control. Soft Foot Correction Program. Vertical and Horizontal Alignment Programs. The only system with Horizontal Program software that requires no manual dimension input measurements therefore eliminating error which provides for a higher degree of. The only system with software that compensates the static and dynamic movement difference which eliminates error and provides for a higher degree of dynamic alignment positioning accuracy. 2 Mark V Digital Indicators with 2 way RS 232 communications which enables a program that guides you through the horizontal alignment process of aligning a shaft or rotor to a housing or container by monitoring the front and rear movement directional lights and monitoring the front and rear shaft movement change values displayed on the display unit or using the automated horizontal jacking supported process. Aligning the manual vertical shaft to the housing and/or the container by monitoring the front and rear movement directional lights and placing. Or removing the front and rear amount of shims that are displayed under the front and rear of the mounting feet. The patented system includes the option to use an Automated Positioning System which reduces the risk of injury involved with manual jacking. The portable removable Automated Horizontal Jacking System starts at. Harris Technology has invented and developed an Advanced Industrial Motor Shaft Alignment System at an affordable price. This system guides you through the alignment process with user friendly Touch Screen graphic icon represented instructions. The lights and numeric displays let you know your exact position proximity within. 00005 accuracy as you are achieving the alignment process. This gives you full control of the speed of moving the motor to achieve the alignment process. The system achieves horizontal alignment without entering user input distance measurements giving reference to the distance between measuring devices and distances from one of the measuring devices to the front and rear of the motor feet. This is a requirement of other systems and the disadvantage is it is difficult to obtain accurate input measurements. The more accurate or abstemious the input measurement gives the most accurate alignment positioning results. This system utilizes calculated information that is based only on dynamic direct response readings without user input information. This system eliminates the disadvantage other systems have and gives the highest possible level of abstemious minute horizontal dynamic directly responsive calculated positioning accuracy. The system compensates for any static movement detected and signals in advance when to stop movement. There are no other system that compensates for static movement caused by applied pressure difference against the motor when you are moving the motor to correct the misalignment which affects the alignment readings. This compensation allows the user to achieve the highest degree of total dynamic manual horizontal positioning accuracy. It is accurate within. 0003 per axis move. Mobile PC or Android PDA as the control platform. Would you rather have a system that only tells you the amount of movement required or a system that has the option of automatically achieving the alignment process for you? The item “HARRIS TECHNOLOGY Shaft Alignment System ROBOTALIGN” is in sale since Tuesday, October 31, 2017. This item is in the category “Business & Industrial\Building Materials & Supplies\Lights & Lighting\Other Lights & Lighting”. The seller is “robotalign” and is located in Ashland, Kentucky. This item can be shipped worldwide.

- Brand: Harris Technology

- Model: RobotAlign System Harris Technology LLC

- Country/Region of Manufacture: United States

- MPN: Does Not Apply